Abrasive Wheel Guards Should Follow Which of the Standards

Cutting off wheels are not designed for use on their side and must be used on their outer periphery only. Wheels used for internal work while within the work being ground.

Fixed Hand Held Grinders Worksafe

I Wheels used for internal work while within the work being ground.

. It must be adjusted so it is located between the operator and the cutting off wheel. Mailing Address 1101 Mail Service Center Raleigh NC 27699-1101. ALWAYS use the correct wheel guard.

Follow manufacturers manual for the safe use of grinder wheel guards. 18 rows From the Abrasive Wheel standard. E Exposure to noise.

Grinding Surface or Face. This guidance primarily focuses on fixed. Abrasive wheels shall be used only on machines provided with safety guards as defined except.

1926303 c Use of abrasive wheels. The guard must be so designed as to allow it to be opened removed on one side. The following topics will be covered.

Safety in grinding machine operations. Mounted wheels used in portable operations 2 inches and smaller in diameter. Key Point The Guard moves up as the machine is used.

Guards rests and accessories. They must be so designed as to be between the operator and the grinding wheel. They may be fitted to either portable hand-held angle grinders or fixed grinding machines mounted to a bench or pedestal.

3 An abrasive wheel shall be disbursed on a first-in first-out basis. If this distance is greater because of the decreased size of the abrasive wheel then a tongue guard must. OSHA requirements are set by statute standards and regulations.

Abrasive wheel machine parts. GUARDS FOR HAND HELD ANGLE AND FACE GRINDERS Guards for type 27 grinding wheels should have a maximum aperture of 185. If not then the machine is SAMPLE.

Department of Labor Physical Address 4 West Edenton St. When using a cut-off wheel with a Type 27 Type 28 guard there is no guard on one side of the wheel protecting the operator in the event of a wheel breakage. Before use check the manufacturers stated running speeds or markings on the grinder and grinder wheel for the maximum speed that it can be used.

What are the topics included in this important document. Do not use makeshift equipment. Below are examples of properly guarded angle grinders.

Applicability of Abrasive Wheel Machinery Guarding Requirements to Scotch-Brite Brand Wheels and Brushes Manufactured by the 3-M Company. Abrasive wheels shall be used only on machines provided with safety guards as defined in the following paragraphs of this section except. Per second ms specified by manufacturers should be marked on every abrasive wheel larger than 80 mm in diameter or on the blotter or identification label which.

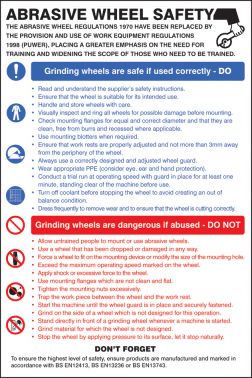

Surface Feet Per Minute. C Hit by flying materials. Guidance subsequent to the repeal of the Abrasive Wheels Regulations 1970 encompassing relevant PUWER 1998 issues and any conflicts with draft European standards.

2 An abrasive wheel shall be stored in a rack bin box or drawer in a manner to prevent damage to the wheel. 1 An abrasive wheel shall not be dropped bumped or rolled. The maximum angular exposure of the grinding wheel periphery and sides shall be not more than 90 degrees except that when work requires contact with the wheel below the horizontal plane of the spindle the angular exposure shall not exceed 125.

Types 16 17 18 18R and 19 cones plugs and threaded hole pot balls where the work offers protection. The combined use of wheel guards eye protection and face shields can reduce the chance and severity of a face injury. 215a2 Do side guards cover.

And iii Types 16 17 18 18R and 19. There are various types of abrasive wheels to suit different applications. In case of straight and taper.

Ii Mounted wheels used in portable operations 2 inches and smaller in diameter. Operating speeds for abrasive wheels. The maximum angular exposure of the grinding wheel periphery and sides shall be not more than 90 deg except that when work requires contact with the wheel below the horizontal plane of the.

B Contact with wheel. Be installed to protect workers from flying fragments in case of wheel breakage. In addition to looking at essential training needs the guide also focuses on details such as.

Shall and Should. 4 An abrasive wheel shall not be stored subject to. Replace damaged guards because if an abrasive wheel breaks while rotating it can cause a serious injury.

Wearing a face-shield can offer the end user. It is the abrasive grinding wheel industry standard for the Safety Requirements for the Use Care and Protection of Abrasive Wheels and most abrasive wheel safety-related questions can be found there. ANSI B71 has been called the Bible for grinding wheel safety for good reason.

Abrasive wheels are typically used within industry for grinding shaping or cutting metallic objects. Guards for cutting off wheels must cover a full 180 area on all sides of the wheel. The guard must be free to move up and down before the machine is used.

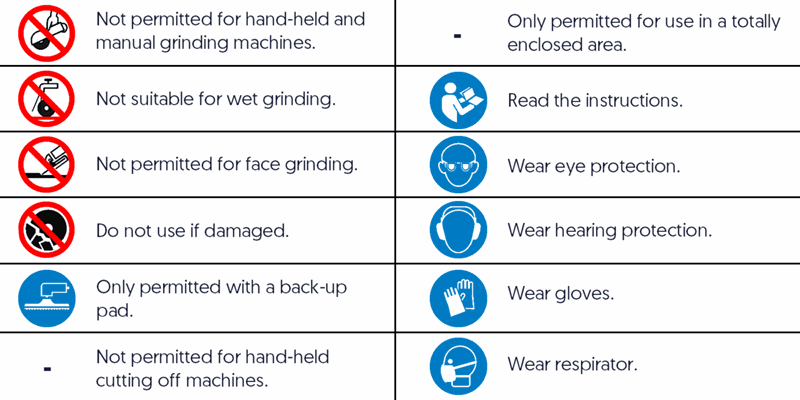

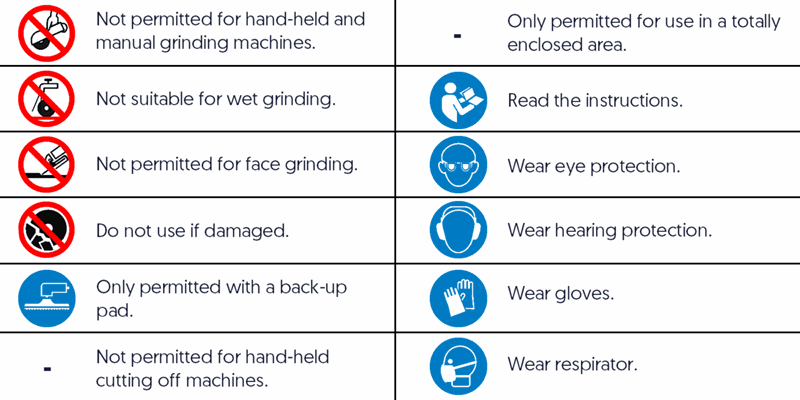

1 the wheel guards with minimum exposure angle 2 the clearance between the work-rest and the wheel should be less than 32 mm 18 3 the protective screen or wear eye protectors Always report any fault or unusual signs of the machine to your foreman or supervisor. 1926303 c 1 Floor stand and bench mounted abrasive wheels used for external grinding shall be provided with safety guards protection hoods. List of Risks associated with abrasive wheel.

Between the safety guard and the top periphery of the wheel must not be more than 14-inch. Floor stand and bench mounted abrasive wheels used for external grinding shall be provided with safety guards protection hoods. Wheel guards for portable machines 32.

Types and characteristics of abrasive wheels. Abrasive Wheel must be mounted on the machine for which it is intended. Bonded abrasive products3 and other standards supporting the health and safety requirements of the Supply of Machinery.

A General requirements - 1 Machine guarding. It is essential therefore that all persons who fit or mount abrasive wheels are trained and competent guards are fitted to the machines and eye protection worn by the operatives all the time. The maximum aperture should not exceed 185.

The machine must also be safe from all perspectives not just an Abrasive Wheels perspective.

Grinding Safety Poster Hse Images Videos Gallery

Top 9 Faqs About Abrasive Wheels Commodious

Comments

Post a Comment